Special Products

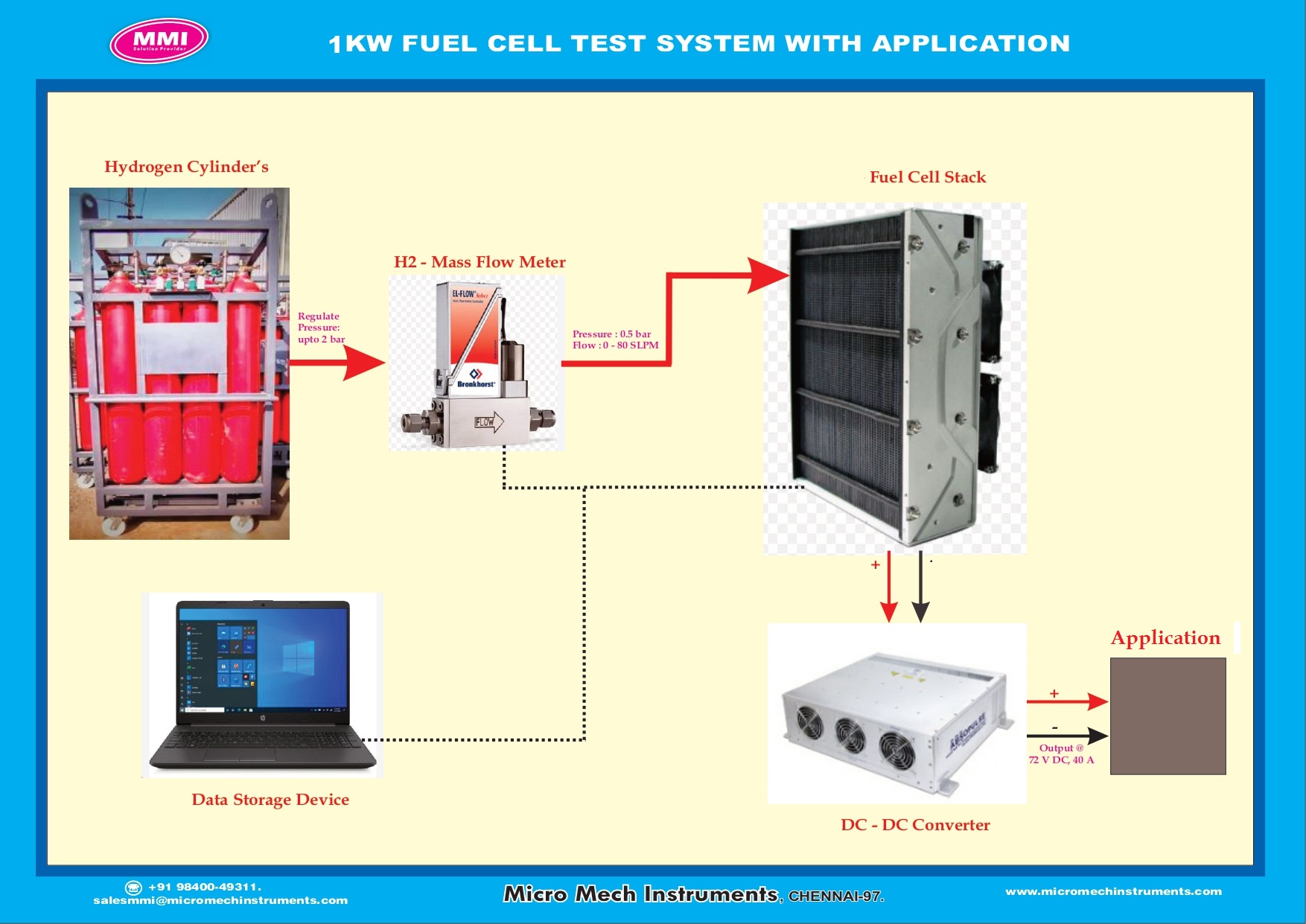

1 KW FUEL CELL TRAINING SYSTEM

Micro Mech Instruments offers a 1 KW Fuel cell Testing and Training Platform. It can include hardware, software, and educational content.

Read More...

Fuel Cell

Micro Mech Instruments offers a 1 KW Fuel cell Testing and Training Platform.It can include hardware, software, and educational content.

Read More...

Vortex Tube Test Rig

To Find the Airflow Rate using hybrid mulitiple range vortex Tube with different pressure range.

Read More...

Twin Cyclinder CRDI Engine OPEN ECU Setup

Twin Cylinder dual fuel CRDI engine setup to find the combustion and open ECU system.

Read More...

VCR Research Engine with Open ECU Setup

Data : Parameter

Bore X Stroke : 87.5 x 110 mm

Displacement : 661 cc

Rated Capacity : 5B.H.P @1500 RPM when

Read More...

PC Based Heat Pump Refrigeration System

This Trainer used to study the effect of heat transfer co efficient. The Unit Complete Enables

Read More...

Computerized Nano Fluids Convective Heat Exchanger

To find the heating and cooling performance of nano fluids using convective heat exchanger for different applications

Read More...

Computerized Hybrid 4-Column Loading Frame

To find the beam and column structual peformance using hybrid four/two coulmns loadind frame.

Read More...

Computerized Four stroke GDI Engine Test Setup

To Measure and Control the Gasoline direct Injection System using open ECU and Combustion analyzer kit.

Read More...

Hybrid Electric Vehicle Research Project

To Develop the E-Vehicle Using Solar and Fuel Cell based Battery to Create Zero Emission Vehicle.

Read More...

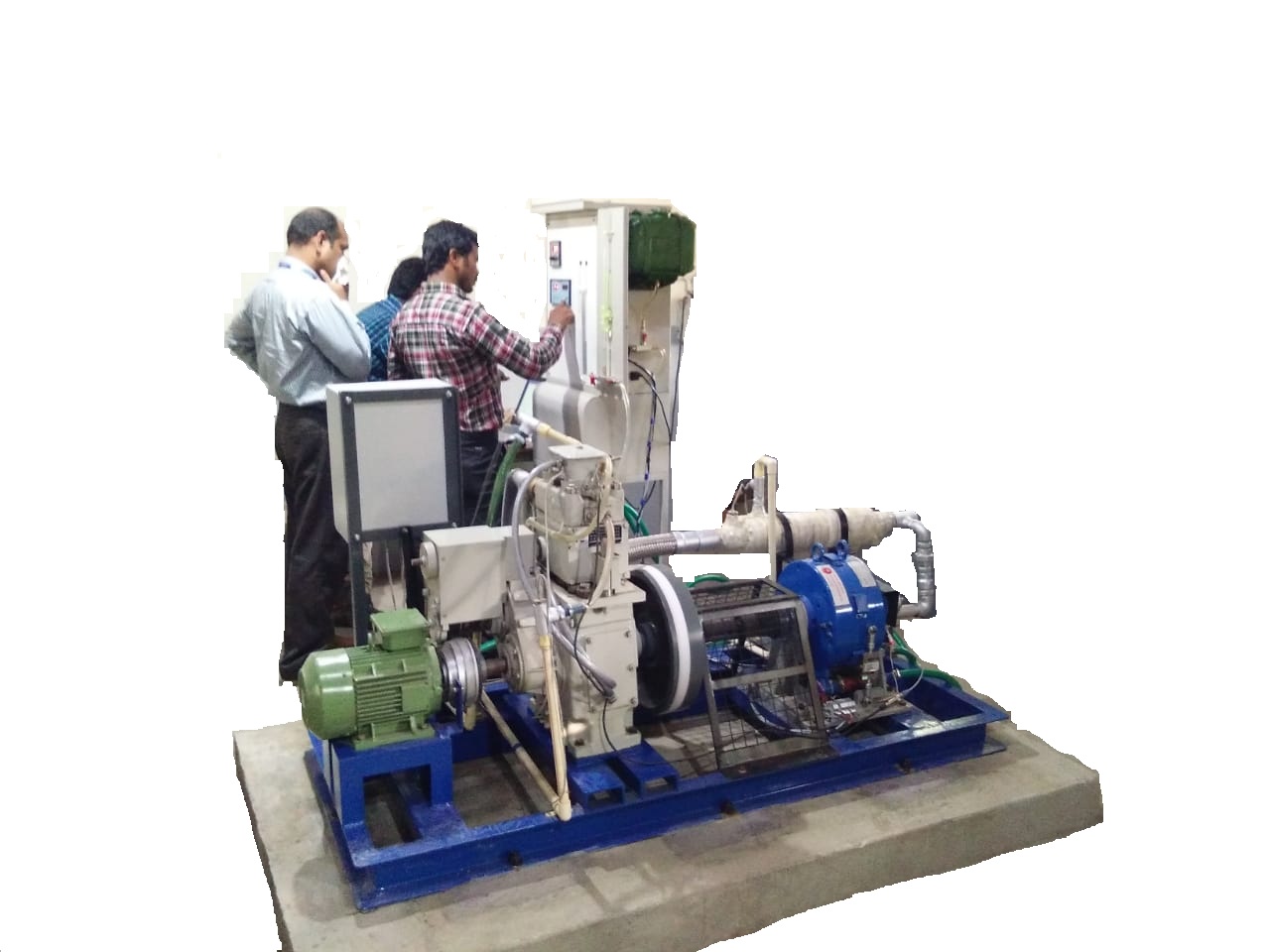

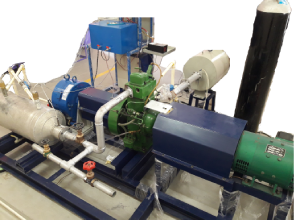

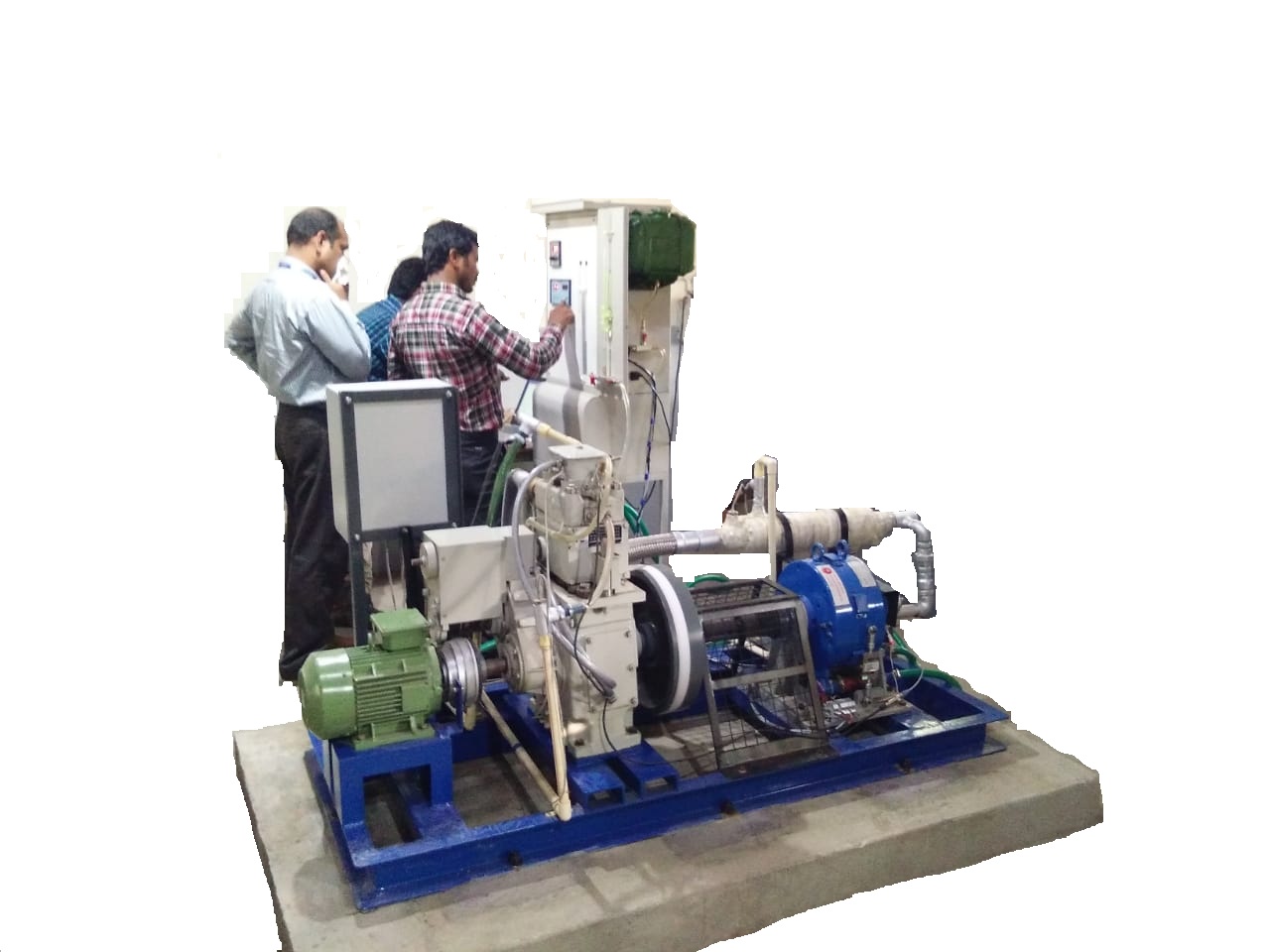

Research Engine using fuel cell & battery development test Rig

This setup consists of engine to test the fuel cell and battery development

Read More...

PC Based Electrolyzer cum Fuel Cell Test Setup

- Load 15 Amps (Max); Panel consisting of PEM fuel cell test assembly, Electrolyzer, Load Bank, Power Supply, Rotameter, Etc.

- Hydrogen generation rate : 100 ml per min. (min.)

- With Flow meters & Digital type indicators for V, A, W, Wh, VA.

- PEM Single Fuel cell Test Assembly Module

- PEM Electrolyzer Module

- Electronic Load Bank

- Power Supply

- Rotameters

- Water Displacement Setup

- Temporary Hydrogen and Oxygen Storage

- Valves / Fittings / Tube / Panel

Servo Controlled 3 Axis Drilling Machine Using PLC

Drilling Operation using PLC

- Table top mounted 3-axis PLC controlled machined suitable for laboratory Learning Activities.

- Crosseshead on the beam moves longitudinally (X-axis); driven by reversible AC synchronous motor

- Complete Gantry structure moves along cylindrical Guideways (Y-axis); driven by 3∅ induction motor (0.75kW, 1400 rpm)

- The cross hand moves vertically (Z-axis); driven by reversible AC synchronous motor.

- Main spindle carrying drill bit is mounted on the crosshead; driven by high speed 1-∅ motor.

- Most suitable for working on lighted metals/materials viz. Acrylic, Plastic, Wood, Aluminium, Copper, Brass.

- Limit switches are provided to prevent over rides.

VCR Research Engine Setup

Data : Parameter Bore X Stroke : 87.5 x 110 mm Displacement : 661 cc Rated Capacity : 5B.H.P @1500 RPM when using High Speed Diesel@CR 17.5:1 Compression Ratio Adjustable from : 5:1 to 11:1 (petrol), 12:1 to 20:1 (diesel) (Extendible up to 22.1 when using bio-diesel blends) Compression Ratio Can be continuously varied without changing the cylinder head Engine Cooling type : Water cooled Fuel Delivery : Carburettor / Fuel Injection Pump, Direct Injection, LPG Gas Kit Ignition System : Compression Ignition adjustable Ignition Coil : Ignition timing -50° BTDC to 10.ATDC Starting : Using induction motor with electromagnetic ClutchSend Enquiry

PC Based Heat Pump Refrigeration System

Compressor Type : Closed Type / KIRLOSKAR Cylinder : Single Discharge : 0 - 10 LPH Tube material : Copper Capacity : 1 TR Refrigerant : 134 a Outer tube dia : 6 mm or &frac1/2;" Pressure drop : 0.5 kgf / cm2 Condenser : Air Cooled Evaporator : Water Cooled Expansion Valves : Capillary Tube & Thermostatic; with Refrigerant Flow Meter Fan (230 volts 2 Amps) : One No ( for Condenser) Freezer box : Evaporator Unit consists of a SS Freezer box Reversing Valve : For heating and cooling purpose Digital Energy Meter : Single Phase Energy meter to measure V, A, W, Wh, VA, Power Factor Pressure Transducer : 0-20 bar Temperature Sensor : 0-99.9°C & RTD Type Temperature Indicator : 5 channel Study : To study effect of heat transfer of coefficient Data Acquisition Card : 8 Digital Input & Output and 8 Single Ended Analog Input / 4 Differential Analog Input Software Based on Lab view SoftwareSend Enquiry

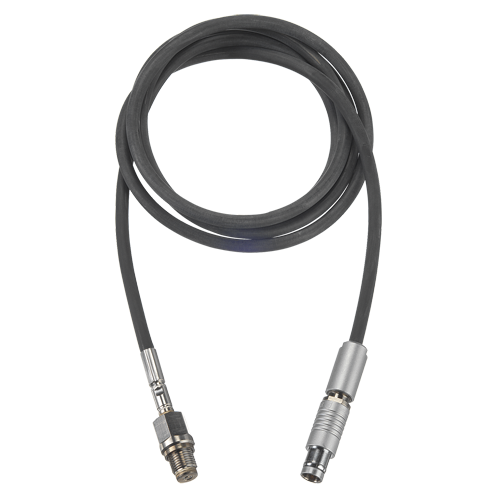

Crank angle Encoder

Technical Specifications Crank angle signal : 720x0,5 °C Speed range : 0 ... 12 000 1/min Temperature rang : - 40 ... 85 °C Electrical connection : cable with plug l = 2 m Weight : 340gSend Enquiry

Pressure sensor

Technical Specifications Pressure range : 0...100 bar Calibration at 200 °C : 0...100 bar Sensitivity (±0,5 %) : 40 mV/bar Frequency range (-3 dB) : 0.016...20'000 Hz Linearity : ≤ ± 1 %FSO Shock : 2000 g Operating temperature range Mounting location : -50...300°C Viton cable connection maximum : 200°C Short overload <1 h : 240°C Electronics : -10...110°C Supply voltage : 7...32 VDC Supply current : 6 mASend Enquiry

Four Axis Robot

Type : RV-4F Maximum Load Capacity (kg) : 4 Maximum Reach Radius : 515 Standard : IP40 Oil mist : IP67 Clean : ISOclass3 Medical Food : IP65Typical Applications

- Machine Tending

- Palletising

- Packaging

- Pick & Place

- Deburring

- Vision ApplicationsInspection

- Material Handling

- Dimensional Measurement (Gauging)

- Assembly (Speedo Meter, Clutch Pack)

- Automated Screw Assembly

Contact Us

Company @ MMI

About Micromech

Address

- Marketing044-28389151

- Purchase044-28389152

- Production044-28389153

- Service+ 91-8220045907

- ☎ Office Phone044 28389151

No.1, 2nd Cross Street, Thendral Nagar, Karapakkam, Chennai - 600 097. Tamilnadu, India. (Near KCG College Back Side Gate)

sales@micromechinstruments.com www.micromechinstruments.com© 2016 Micro Mech Instruments | Site Map