Mechatronics

Basic Pneumatic Trainer

Basic Electro Pneumatic with PLC

Basic Electro Pneumatic

Speed Control of AC Motor

Speed Control of DC Motor

PID Controller Interfacing

8051 Micro Controller

Computerised Data Logging System

Design and Testing of Fluid Power Circuits

Basic Pneumatic Trainer

The Trainer is Useful to Study the basic Level Pneumatic experiments, Consisting of components like FRL, Pneumatic Cylinders, Directional Control Valves, Pilot operated Valves, Logic Valves etc.,

Send EnquiryBasic Electro Pneumatic with PLC

The Trainer is Useful to Study the basic Level Electro Pneumatic experiments, Consisting of components like FRL, Pneumatic Cylinders, Directional Control Valves, Solenoid operated Valves, Reed Switch Programmable Logic Controller to do the Experiments etc.,

Send EnquiryBasic Electro Pneumatic

The Trainer is Useful to Study the basic Level Electro Pneumatic experiments, Consisting of components like FRL, Pneumatic Cylinders, Directional Control Valves, Solenoid operated Valves, Reed Switch Electric I/O Module to do the Experiments etc.,

Send EnquirySpeed Control of AC Motor

The Details of this module are as follows

- One Sensor provided to sense the speed of AC motor

- Provision to select open and closed loop study

- Thirstier based power driver provided to drive the AC Motor

- Miniature illuminated rocker switch provided to power on the driver unit

- All the components are mounted on attractive frame with mimic diagram

Speed Control of DC Motor

This module consists of, speed control of PMDC motor, PWM based driver

The details of this module are as follows

- One 12Volt PMDC motor

- Speed sensor to sense the speed of the motor at 0-1500 rpm speed.

- One amplifier F/V converter Provided

- The PMDC motor with Speed sensor is fixed on a mechanical frame.

- To study the speed control of the DC motor

PID Controller Interfacing

- Microcontroller based CPU card

- 2 Row x 16 Column LCD Dot Matrix with back light Display Alphanumeric Display

- Single Channel Single ended Analog Input Range : (0-5)V DC

- Single Channel Analog Output (0-5) Volt

- 4 Number of keys provided to give set point, increment, Decrement function etc.

- In-Built regulated power supply provided.

8051 Micro Controller

Specification:

PROCESSOR : 8051 Microcontroller at 12 MHz or equivalent

MEMORY : 8 K Bytes of EPROM expandable to 32 K Bytes.

8 K Bytes of RAM expandable to 32 K Bytes with battery backup

- On chip RS232 Compatible

- 48 Digital I/O lines using 8255 terminated in two 26 Pin FRC Connectors

- All CPU address, data, and control signals are terminated in a 50 pin FRC Connector for connecting the Application Experiment boards.

- SMPS Power supply

- Input: 230V AC @ 50 Hz

- Output: +5 Volts / 1 Amp

- +12 Volts / 100 ma

Computerised Data Logging System

Flow Measurement

- One Miniature Pump Provided to control the Water Flow

- One Flow Sensor provided to measure the flow rate

- Necessary Controller provided to interface the PC

- Mechanical Setup Provided

- Lab View Software Interfacing Facility Provided

- Provided only for the measurement of Pressure

- One Air Tank Setup Provided to Measure the Pressure of the Air

- One Pressure sensor Provided

- Necessary Controller provided to interface the PC

- Mechanical Setup Provided

- Lab View Software Interfacing Facility Provided

- Provided only for the measurement of Flow

- A heater provided to heat the water

- RTD Provided to measure the Temperature

- Necessary Controller provided to interface the PC

- Mechanical Setup Provided

- Lab View Software Interfacing Facility Provided

- Provided only for the measurement of the Temperature

- 08 Digital Inputs 11-bit (SE) resolutions Up to 50 kS/s sample rate

- 08 Digital Outputs 11-bit (SE) resolutions Up to 50 kS/s sample rate

- 08 single-ended or 4 differential analogue inputs

- 02 12-bit analogue outputs,One Counter

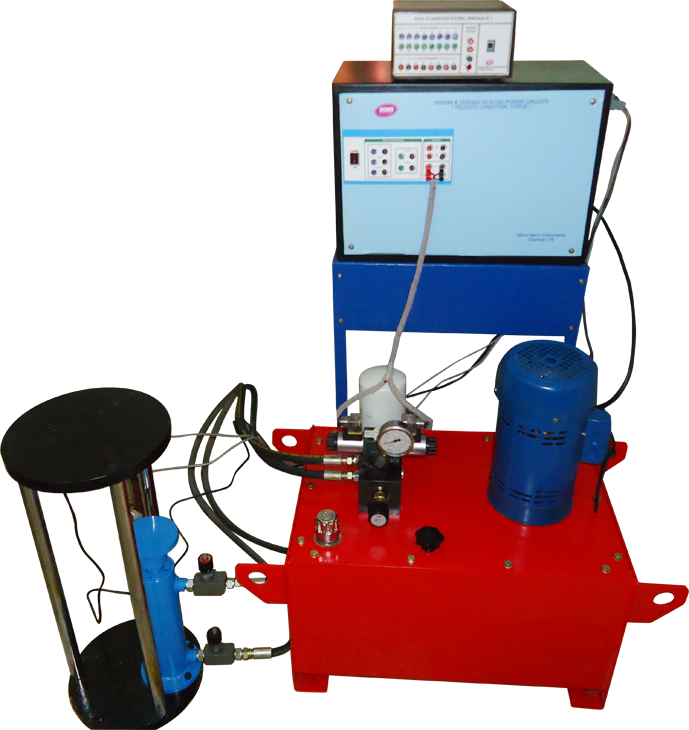

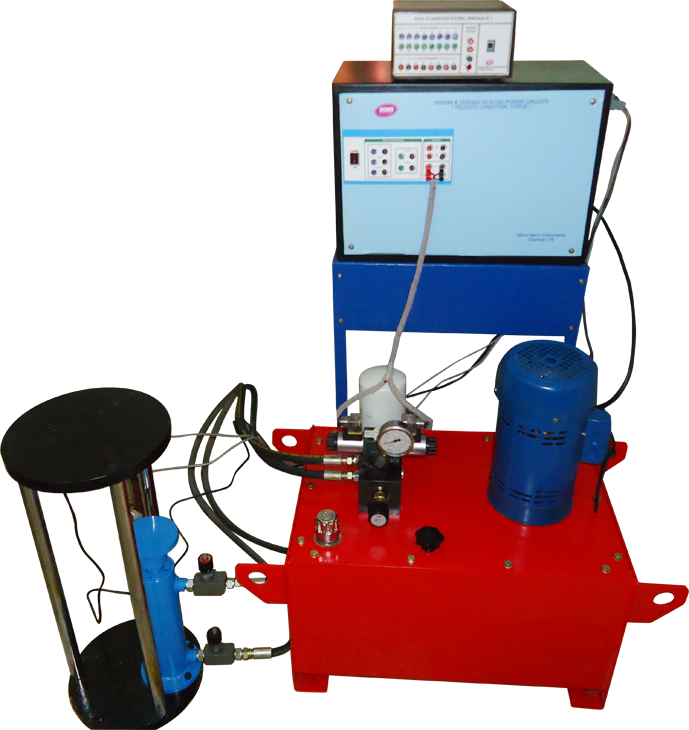

Design and Testing of Fluid Power Circuits

- This trainer kit useful to study the Direction, Velocity, Force.

- A Load cell (300 KG), Proximity Sensors to sense the Velocity.

- A Data Acquisition system provided to Logging the Data in the System.

- This setup is useful in studying the Fluid Power applications.

- Marketing044-28389151

- Purchase044-28389152

- Production044-28389153

- Service+ 91-8220045907

- ☎ Office Phone+91-8220045907

No.1, 2nd Cross Street, Thendral Nagar, Karapakkam, Chennai - 600 097. Tamilnadu, India. (Near KCG College Back Side Gate)

sales@micromechinstruments.com www.micromechinstruments.com© 2016 Micro Mech Instruments | Site Map